CENTRE OF EXCELLENCE IN 3D PRINTING

(UNDER DEPARTMENT OF MECHANICAL ENGINEERING)

Additive manufacturing is an apt term for the technologies that create three-dimensional items by layering material, whether it’s plastic, metal, concrete, or, one day, human tissue. The use of a computer, 3D modelling software (Computer Aided Design or CAD), machine equipment, and layering material are all common in additive manufacturing technologies. Following the creation of a CAD sketch, additive manufacturing equipment reads data from the CAD file and layers or adds liquid, powder, sheet material, or other materials in a layer-by-layer method to build a 3D item.

3D printing, rapid prototyping, direct digital manufacturing, layered manufacturing, and additive fabrication are all subsets of additive manufacturing.

3D printing is an additive technology used to manufacture parts. It is ‘additive’ in that it doesn’t require a block of material or a mould to manufacture physical objects, it simply stacks and fuses layers of material. It’s typically fast, with low fixed setup costs, and can create more complex geometries than ‘traditional’ technologies, with an ever-expanding list of materials. It is used extensively in the engineering industry, particularly for prototyping and creating lightweight geometries.

The possibilities for 3D printing applications are endless. 3D printing is now being utilised to produce end-use goods in aeroplanes, dental restorations, ornament, medical implants, defence, oil & gas, space, vehicles, fashion and other industries.

The goal of the Center of Excellence is to bring together industries, R&D institutions, and academics to hold manufacturing problems using 3D printing technologies. Through access to 3D printing technology, the Center of Excellence aims to bridge the gap between basic research, product design and development, and provide cutting-edge solutions. The major goal of the Center of Excellence is to create an ecosystem that will educate industry, R&D, and academia on 3D printing technologies. The facility also encourages international collaborations in cutting-edge 3D printing technology.

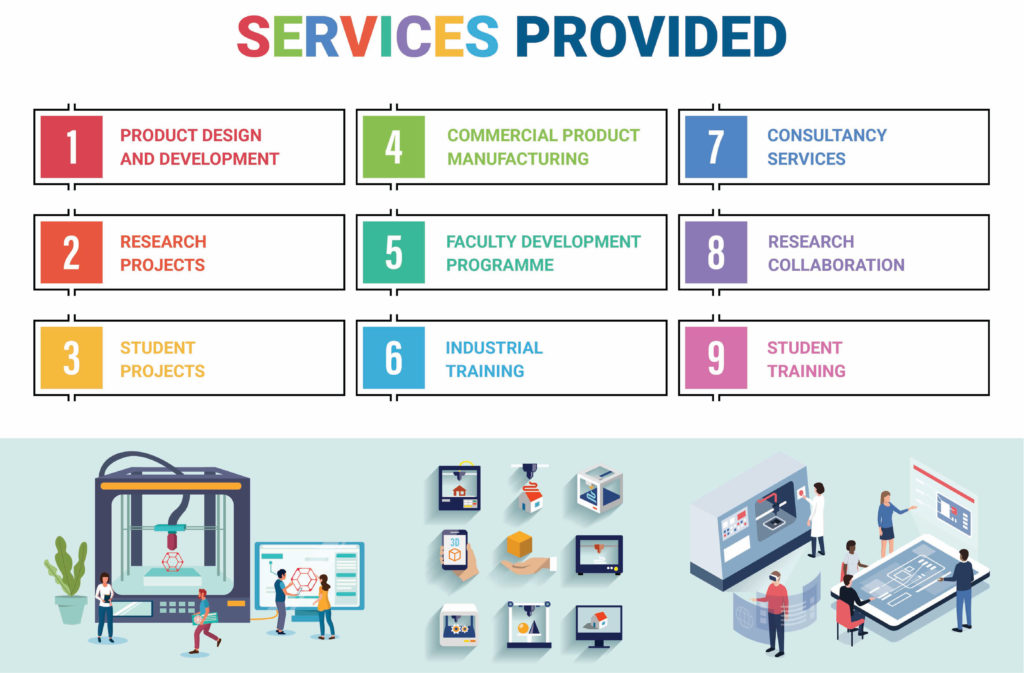

The Center of Excellence also aims to promote commercialization, academic and research activities among practising engineers, industries, students, and faculty members, as well as provide consulting and necessary support services to industries involved in 3D scanning of components, generation of 3D models from physical models, post-processing of the models, inspection, and 3D printing of components. One dual nozzle 3D printer, one single nozzle 3D printer, and one 3D scanner are available at the Center of Excellence. The major objectives of the Center of Excellence are as follows:

- To closely work with different industries to provide 3D printing related services.

- To conduct hands on courses on 3D printing for faculty members, staffs and students.

- To provide internship opportunities to student.

- To provide experimental facilities for student projects.

- To provide experimental facilities for researchers pursuing Masters / PhD in related areas.

- To organization faculty development programme in 3D printing.

- To provide case-based 3D printing

- To provide consultancy services.

- To collaborate with national and international institutes and societies for research and training programme.

Sl. No. | Item | Details |

1 | 3D Printer Arya 300+ Dual Nozzle | Print Size/Build Volume- 300 X 300 X 300 (mm3) |

2 | 3D Printer Arya XL Single Nozzle | Print Size/Build Volume- 500 X 500 X 500 (mm3) |

3 | Printing resolution | 100 microns |

4 | Technology | Fused Deposition Modeling (FDM) |

5 | Available 3D printing filaments | PLA+ / ABS+ / PETG |

6 | 3D Scanner | CREALITY CR SCAN 01 |

Dr. Prasenjit Chatterjee, Dean – Research and Consultancy

E-mail id: p.chatterjee@mckvie.edu.in

PEOPLE ASSOCIATED WITH CENTER OF EXCELLENCE:

Dr. Jaideep Dutta

Dr. Abhijit Dutta

Mr. Nabankur Mandal

Mr. Swaraj Biswas

Mr. Nabin Kumar Mondal

Mr. Arijit Ghosh